At the base of the flexible polyurethane foam production there are three main raw materials: POLYOL, ISOCYANATE, and WATER; exactly water, an essential element for life, is the reagent that leads to the expansion and growth of foam

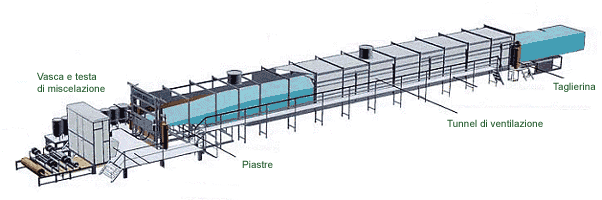

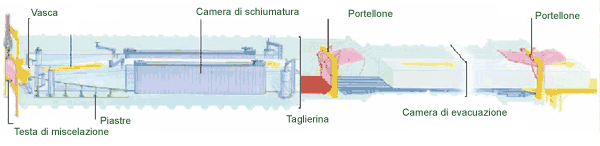

POLYURETHANE PRODUCTION IN CONTINUOS (TRADITIONAL PRODUCTION TECHNIQUE)

he raw materials, which are placed in their relative production tanks, are dosed with other additives carefully selected inside the mixing top in which the reaction start takes place. The process occurs without using damaging substances for the environment: complementary agents, like CFC and METHYLENE CHLORIDE, are excluded from the production process both because they’re not compatible with the environmental protection and because they are harmful for the security and health of the final users.

From the mixing top the foam arrives in a tank from which it overflows then on a conveyor belt that goes through a tunnel, which is kept under strong aspiration. The reactions of expansion and polymerization develop in about 1/3 minutes; during this interval time the block achieves the final dimensions. Once that the block gets out from the tunnel, it is cut into variable length boards, which are sent in a maturation system.

The completion of the polyurethane reaction is obtained in a period of time between 24 and 72 hours from the mixing of the components, later the boards are stored into warehouses.

After that, the polyurethane block is picked up in order to be submitted to further cutting operations.